How to handle the surface of stretch wrapping film correctly

How to handle the surface of stretch wrapping film correctly?

With the continuous emergence of various new materials, new equipment and new processes, the stretch wrapping film will develop towards the direction of diversification, specialization and multi-functional composite film.

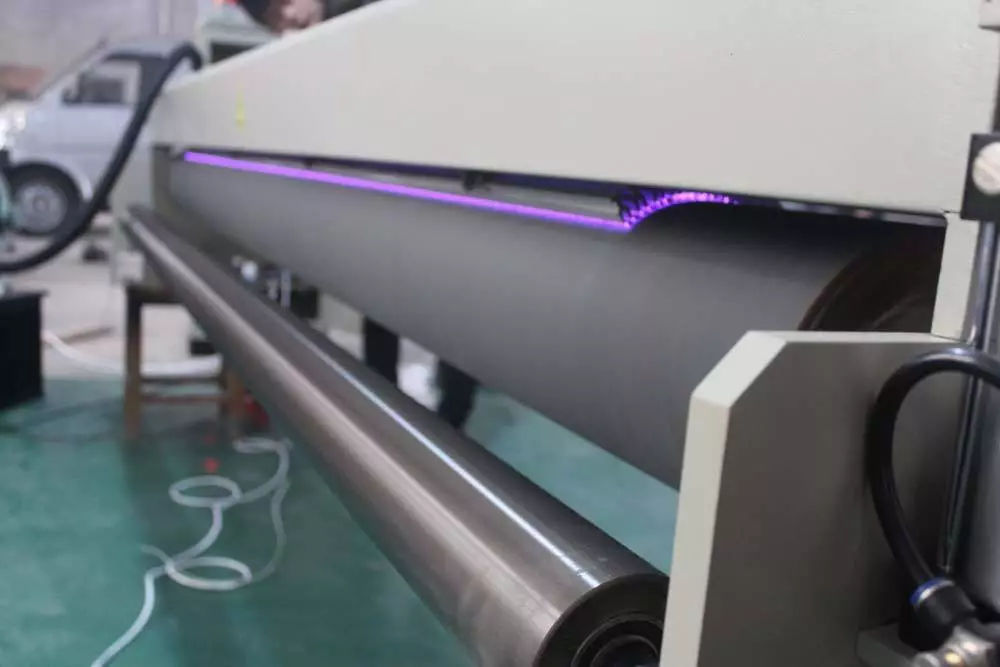

The longest method for surface treatment of stretched film is corona treatment. The basic principle is: by applying high temperature between the metal electrode and the corona treatment roller (usually a high-temperature, ozone-resistant, and highly insulating silicone rubber roller).

The high-frequency and high-voltage power supply generates electric discharge, which ionizes the air and forms a large amount of ozone. At the same time, high-energy electric sparks hit the surface of the film.

The high-frequency and high-voltage power supply generates electric discharge, which ionizes the air and forms a large amount of ozone. At the same time, high-energy electric sparks hit the surface of the film.

The magnitude of the wet tension on the surface of the corona treated stretched film is related to factors such as the voltage applied to the electrode, the distance between the electrode and the corona treatment roll. Of course, corona treatment should be moderate, not that the higher the intensity of corona treatment, the better. It is worth noting here that air should be avoided between the stretch wrap film and the corona treatment roller, otherwise the reverse side of the film may also be corona treated.

Consequences caused by negative corona:

1. Anti-sticking phenomenon of ink printing may occur.

2. The transfer of the aluminized layer will occur during the aluminum plating, and the transfer of the glue layer will occur during the glue coating. The main measure to prevent corona on the reverse side of the film is to adjust the pressure of the rubber pressing roller in front of the corona treatment roller. The pressure at both ends of the pressing roller must be the same and the pressure must be appropriate. In addition, the corona roller and the pressure roller must undergo strict dynamic and static balance tests. The radial runout is required to be less than 0.05 mm. The purpose is to ensure that the stretch wrap film enters the corona roller smoothly and prevents air from being trapped, so as to avoid back-side corona. The phenomenon.

Stretch film needs to have good transparency in use. Therefore, the GB/T2410-1980 transparent plastic transmittance and haze test method was selected. Most domestic production enterprises also use this standard to assess.

In order to reflect whether the stretch film can protect the product from moisture or moisture absorption in the sea or in an environment with high humidity, that is, the sealability after wrapping, it is tested in accordance with the GB/T1037-1988 plastic film and sheet water vapor permeability test method standard The amount of water vapor permeation to be assessed.

Note: There are many types of stretch stretch film, such as PE stretch film, stretch stretch film, PVC stretch film, etc. The production process and performance of each are quite different. Like PE stretch film, the performance is moderate, but it is environmentally friendly and healthy. Stretch stretch film has strong mechanical properties and is suitable for large packaging and long-distance transportation of goods, while PVC stretch film is used in specific places.

评论

发表评论